Rapid Prototyping in China: An Overview

The landscape of product development has shifted profoundly in recent years, and rapid prototyping in China has emerged as a significant player in this revolution. With its combination of advanced technology, skilled labor, and competitive costs, China has positioned itself as a leader in the manufacturing sector, particularly in rapid prototyping. This article delves into the intricacies of rapid prototyping, its benefits, and why China has become the go-to destination for businesses seeking to innovate and streamline their product development processes.

What is Rapid Prototyping?

At its core, rapid prototyping refers to a group of techniques used to quickly fabricate a scale model or prototype of a physical part or assembly. The prototype is built using computer-aided design (CAD) software, and the process allows for the rapid alteration and adjustment of designs in response to feedback.

Some common methods of rapid prototyping include:

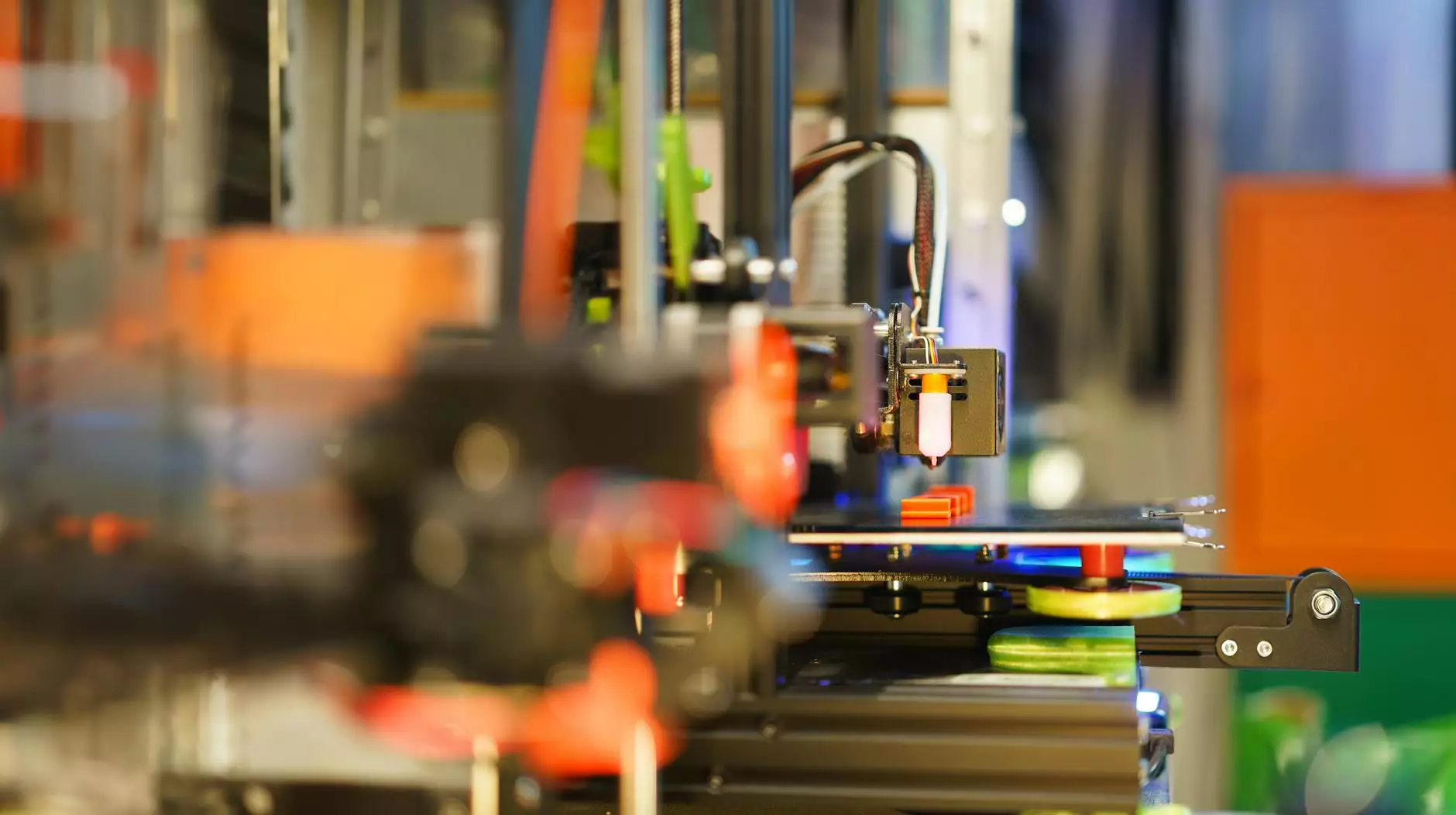

- 3D Printing: The most well-known method, involving the additive manufacturing of materials layer by layer.

- Computer Numerical Control (CNC) Machining: This method uses precise cutting tools to create prototypes from solid blocks of material.

- Stereolithography (SLA): A technique that uses a laser to cure liquid resin into hardened plastic.

- Selective Laser Sintering (SLS): Similar to SLA, but uses powdered materials that are fused by lasers.

Why Choose Rapid Prototyping in China?

China has become synonymous with manufacturing excellence, and when it comes to rapid prototyping, several factors contribute to its dominance:

1. Cost Efficiency

One of the primary advantages of choosing rapid prototyping in China is cost efficiency. Lower labor costs, coupled with an established supply chain, allow Chinese manufacturers to offer competitive pricing without compromising quality. This affordability enables businesses to produce high-quality prototypes at a fraction of the cost compared to other countries.

2. Advanced Technology

China's world-class manufacturing facilities are equipped with the latest technology in rapid prototyping. From high-end 3D printers to advanced CNC machines, the country's commitment to adopting cutting-edge technology ensures that businesses receive the most precise and innovative solutions. This technological edge translates into faster production times and more accurate prototypes.

3. Skilled Workforce

China boasts a vast pool of highly trained professionals in engineering and manufacturing. The country has invested heavily in technical education, yielding a workforce that is not only skilled but also adaptable to new technologies and methods. This workforce is essential for the rapid iteration process that prototyping requires.

4. Flexibility and Customization

Rapid prototyping in China allows companies to benefit from a high degree of flexibility and customization. Chinese manufacturers often offer tailored solutions, enabling businesses to produce prototypes that meet their specific requirements. This flexibility is crucial in the early stages of product development when design changes are frequent.

The Process of Rapid Prototyping in China

The process of rapid prototyping involves several stages, each crucial to creating a successful final product:

1. Idea Development

The first stage is to transform an idea into a tangible product concept. This involves extensive research, brainstorming, and initial sketches. In China, companies often collaborate closely with clients to understand their vision.

2. Design and CAD Modeling

Once the concept is clear, the next step is developing a digital model using CAD software. This phase is critical as it serves as the blueprint for the prototype. Chinese manufacturers employ skilled designers who excel at translating ideas into detailed 3D models.

3. Prototyping

Following the design phase, the prototype is produced using one of the many rapid prototyping techniques. This stage allows for immediate feedback on the design and functionality, enabling quick adjustments as needed. In China, the speed and efficiency of this stage have been honed to meet the demands of global businesses.

4. Testing and Iteration

After the prototype is created, rigorous testing is conducted to assess its functionality and performance. Feedback from these tests leads to further modifications. Chinese manufacturers are well-known for their iterative approach, ensuring that the final product aligns closely with the client’s specifications.

5. Final Production

Upon completing the testing phase and final adjustments, the prototype can move towards full-scale production. Chinese manufacturers excel at transitioning from small-scale prototyping to high-volume production, ensuring a seamless process.

Industries Benefiting from Rapid Prototyping in China

An array of industries can leverage the advantages of rapid prototyping in China. Some notable sectors include:

1. Automotive

The automotive sector is constantly innovating, and rapid prototyping enables manufacturers to develop new components and features quickly. Companies in this industry rely on China for producing cost-effective prototypes for testing and validation.

2. Consumer Electronics

In the fast-paced world of consumer electronics, speed to market is essential. Rapid prototyping in China helps companies design and test new products, ensuring they stay ahead of the competition.

3. Aerospace

The aerospace industry, with its stringent standards and requirements, benefits significantly from rapid prototyping. Chinese manufacturers provide the precision and reliability needed for developing advanced components.

4. Medical Devices

Rapid prototyping is pivotal in the medical industry, where prototyping devices can lead to crucial innovations. China’s manufacturers comply with international standards, ensuring quality and safety.

Challenges and Considerations

While there are numerous advantages to rapid prototyping in China, businesses must navigate several challenges:

1. Communication Barriers

Effective communication is vital for successful collaboration. Misunderstandings can arise due to language differences or cultural nuances. It’s important for businesses to establish clear communication channels with their Chinese partners.

2. Quality Control

Maintaining consistent quality can be a challenge when working with overseas manufacturers. It’s crucial to conduct thorough due diligence and possibly visit factories to ensure that they meet the required standards.

3. Intellectual Property Concerns

There are inherent risks regarding intellectual property when sharing proprietary designs or concepts with foreign manufacturers. Companies should take necessary precautions, such as non-disclosure agreements, to protect their innovations.

Finding the Right Partner for Rapid Prototyping in China

Choosing the right manufacturing partner in China is essential for maximizing the benefits of rapid prototyping:

1. Research Potential Partners

Take the time to research potential rapid prototyping manufacturers in China. Look for firms with a strong track record, positive reviews, and case studies.

2. Evaluate Capabilities

Assess the capabilities of potential partners regarding their technology, workforce, and ability to meet specific project requirements. Ensuring they specialize in the needed prototyping methods is critical.

3. Communication and Collaboration

Initiate open discussions about your project needs and expectations. A responsive manufacturer that demonstrates a willingness to collaborate will foster a better partnership.

4. Quality Assurance Practices

Inquire about the quality assurance processes in place. A reliable manufacturer will have rigorous quality control measures to ensure the prototypes meet industry standards.

Conclusion

In conclusion, rapid prototyping in China offers businesses a remarkable opportunity to accelerate their product development cycles. With cost-effective solutions, advanced technology, a skilled workforce, and a deep understanding of various industries, Chinese manufacturers are well-equipped to meet the demands of modern innovation. By carefully navigating the challenges and selecting the right partner, companies can harness the power of rapid prototyping to bring their ideas to life faster and more efficiently than ever before. In a global marketplace that values speed and adaptability, embracing rapid prototyping in China can be a strategic advantage for businesses aiming to thrive and expand.